It is necessary to use injection molding for making polymer lens, generary.

Injection molding needs high initial cost and much MOQ. Under these circumstances, it is difficult to manufacture small quantity and to prototype. This CNC machined optics service is intented to deal with quickly prototyping, small lot and acuracy for polymer optics.

Why is a polymer lens prototype difficult?

Prototyping for polymer lenses used to be manufactured by injection molding.

Because, it used to be common knowledge that prototyping for acrylic by direct milling is impossible to achieve high precision.

For example, one-direction positioning accuracy for a certain machining center, that prototyping factories use mainly, is 6 microns.

The linear defects are remained on that surface of a lens made by this accuracy, so it is finished with thermal deformation with “Polishing by a polishing paper” and “Pressing a rotating buff cloth on it”.

It is already accuracy not called “lens” when using paper.

Besides, it is become transparent by buffing and thermal transformation, so prototyping company’s lens accuracy was less than being paid no attention by Researcher and Developer.

It is difficult to use as optics that handle the light, wavelength about 0.5 micron, even if processing is the best, due to quadrant glitches and the geometry which is rounded in micron order even if it is calculated in submicron order.

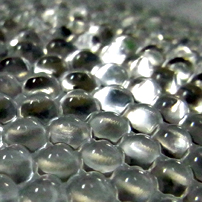

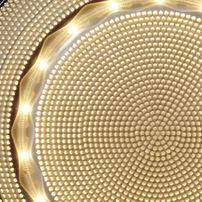

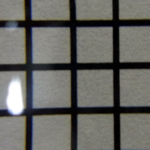

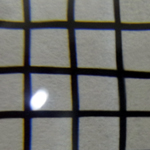

Fig. 1 processing comparison by submicron accuracy machining center and a certain machining center

The pictures are a grid taken through the lens by submicron accuracy machining and a certain machining center.

Left is a grid taken through the lens by submicron machining in-house, MC430L, with polishing by hand.

Right is a grid taken through the lens by a certain machining center with finished by polishing paper and buffing.

Right lens is good transparency, but the grid is distorted. Difference of Machining accuracy appears same as difference of lens accuracy.

Improving accuracy for Direct milling polymer lens

Machining depends on the performance of the machining in practice.

C&S aim to process higher accuracy lens for prototyping polymer lens with higher grade submicron order machining.

Moreover, driving XYZ axis by linear motor is not cause on lens surface to notch with quadrant glitches in principle.

Addition, the aspherical processing machine used for one-axis lens processing is more precise, the accuracy is 10 nm order.

The most important thing is “craftsmanship” of hand-work

Machined lens is processed within surface roughness Ra 0.1 by those machine accuracies, but the lens has not been transparent or specular yet.

Then, the finishing step is “craftsmanship” of hand-work.

It is necessary that know-how and proficient skill for polishing finish.

Examples

Contact

お気軽にお問い合わせください!